Why can a broken bridge aluminum alloy sliding window simultaneously offer high aesthetics, strong sealing, and ultra-low energy consumption?

Release Time : 2025-11-27

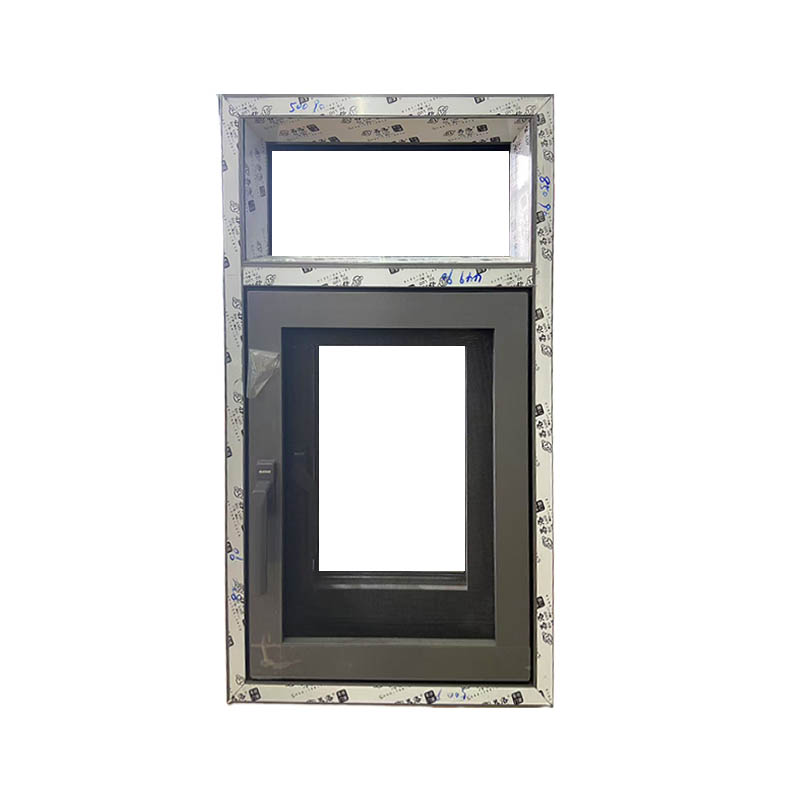

In the modern architectural window and door industry, consumer demands for windows have long surpassed the basic function of "protecting from wind and rain," shifting towards a comprehensive performance that integrates aesthetics, energy efficiency, sound insulation, and durability. The broken bridge aluminum alloy sliding window is an ideal solution to this demand. It cleverly combines the robust durability of aluminum alloy, the spatial advantages of a sliding structure, and the energy-saving characteristics of "broken bridge" thermal insulation technology, making it widely favored in high-end residences, energy-efficient buildings, and even commercial spaces. Its ability to simultaneously achieve high aesthetics, strong sealing, and ultra-low energy consumption stems from the synergistic innovation of materials, structure, and manufacturing processes.

1. Broken Bridge Structure: Blocking Heat Conduction for Ultra-Low Energy Consumption

Traditional aluminum alloys have high thermal conductivity, easily forming "cold bridges" in winter, leading to rapid heat loss from the interior; in summer, they become "high-speed channels" for external heat. The core of the broken bridge aluminum alloy window lies in embedding a low-thermal-conductivity thermal insulation strip between the inner and outer aluminum profiles, physically blocking the metal pathway and forming a "thermal bridge."

2. Precision Sealing System: Multiple Lines of Defense Against Wind, Rain, and Noise

Although sliding windows were once considered less airtight than casement windows due to structural limitations, modern broken bridge aluminum alloy sliding windows have completely overturned this impression through multi-track sliding and multi-layer sealing strip designs. There are typically three or more seals between the window sash and the frame: a top windproof strip, a middle EPDM airtight layer, and a bottom drainage and anti-seepage structure working in tandem. Some high-end products also employ the isobaric chamber principle to balance internal and external air pressure and prevent rainwater backflow.

3. Minimalist Aesthetics and Wide View: A Perfect Blend of Beauty and Practicality

The high strength of the broken bridge aluminum alloy profile allows for a narrow frame and a highly transparent design. The sliding structure requires no outward opening space, making it particularly suitable for balconies, floor-to-ceiling windows, and other scenarios where a wide view and efficient interior layout are crucial. A variety of surface treatments are available—fluorocarbon coating, powder coating, wood grain transfer, etc.—retaining a metallic texture while matching various decorating styles such as modern, neo-Chinese, and minimalist. Clean, crisp lines and a light, airy feel allow ample natural light, enhancing the sense of space and quality of life.

4. Optimized Sliding Structure: Smooth, Durable, and Easy to Clean

Thanks to high-precision molds and CNC machining, the sliding system of thermally broken aluminum alloy sliding windows generally uses dual-bearing silent rollers and stainless steel tracks, offering strong load-bearing capacity, smooth sliding, and a lifespan of over 100,000 cycles. Some products are equipped with buffer anti-collision devices and child safety locks, balancing comfort and safety. Furthermore, the sliding opening mechanism facilitates cleaning the outside of the glass from the inside, making it especially suitable for high-rise residential buildings and solving the pain point of "difficult window cleaning."

5. Green Building Material Attributes: Environmentally Friendly and Reliable Throughout the Entire Lifecycle

Aluminum alloy is 100% recyclable, and the thermally broken structure contains no volatile harmful substances, meeting green building evaluation standards. Its excellent weather resistance ensures a service life of over 20 years, reducing replacement frequency and resource waste, making it more sustainable in the long run.

The success of broken bridge aluminum alloy sliding windows lies in its breaking the traditional perceptions that "energy saving sacrifices aesthetics," "sealing affects the view," and "durability equals bulkiness." By using thermal break bridges to block energy loss, multiple seals to protect against wind and rain, and minimalist design to illuminate spatial aesthetics—it is not just a window, but a concrete expression of modern living's pursuit of a high-quality lifestyle. Driven by both carbon reduction goals and consumption upgrades, this type of door and window product, which integrates technology, art, and practicality, is becoming an indispensable "energy-saving eye" for future buildings.

1. Broken Bridge Structure: Blocking Heat Conduction for Ultra-Low Energy Consumption

Traditional aluminum alloys have high thermal conductivity, easily forming "cold bridges" in winter, leading to rapid heat loss from the interior; in summer, they become "high-speed channels" for external heat. The core of the broken bridge aluminum alloy window lies in embedding a low-thermal-conductivity thermal insulation strip between the inner and outer aluminum profiles, physically blocking the metal pathway and forming a "thermal bridge."

2. Precision Sealing System: Multiple Lines of Defense Against Wind, Rain, and Noise

Although sliding windows were once considered less airtight than casement windows due to structural limitations, modern broken bridge aluminum alloy sliding windows have completely overturned this impression through multi-track sliding and multi-layer sealing strip designs. There are typically three or more seals between the window sash and the frame: a top windproof strip, a middle EPDM airtight layer, and a bottom drainage and anti-seepage structure working in tandem. Some high-end products also employ the isobaric chamber principle to balance internal and external air pressure and prevent rainwater backflow.

3. Minimalist Aesthetics and Wide View: A Perfect Blend of Beauty and Practicality

The high strength of the broken bridge aluminum alloy profile allows for a narrow frame and a highly transparent design. The sliding structure requires no outward opening space, making it particularly suitable for balconies, floor-to-ceiling windows, and other scenarios where a wide view and efficient interior layout are crucial. A variety of surface treatments are available—fluorocarbon coating, powder coating, wood grain transfer, etc.—retaining a metallic texture while matching various decorating styles such as modern, neo-Chinese, and minimalist. Clean, crisp lines and a light, airy feel allow ample natural light, enhancing the sense of space and quality of life.

4. Optimized Sliding Structure: Smooth, Durable, and Easy to Clean

Thanks to high-precision molds and CNC machining, the sliding system of thermally broken aluminum alloy sliding windows generally uses dual-bearing silent rollers and stainless steel tracks, offering strong load-bearing capacity, smooth sliding, and a lifespan of over 100,000 cycles. Some products are equipped with buffer anti-collision devices and child safety locks, balancing comfort and safety. Furthermore, the sliding opening mechanism facilitates cleaning the outside of the glass from the inside, making it especially suitable for high-rise residential buildings and solving the pain point of "difficult window cleaning."

5. Green Building Material Attributes: Environmentally Friendly and Reliable Throughout the Entire Lifecycle

Aluminum alloy is 100% recyclable, and the thermally broken structure contains no volatile harmful substances, meeting green building evaluation standards. Its excellent weather resistance ensures a service life of over 20 years, reducing replacement frequency and resource waste, making it more sustainable in the long run.

The success of broken bridge aluminum alloy sliding windows lies in its breaking the traditional perceptions that "energy saving sacrifices aesthetics," "sealing affects the view," and "durability equals bulkiness." By using thermal break bridges to block energy loss, multiple seals to protect against wind and rain, and minimalist design to illuminate spatial aesthetics—it is not just a window, but a concrete expression of modern living's pursuit of a high-quality lifestyle. Driven by both carbon reduction goals and consumption upgrades, this type of door and window product, which integrates technology, art, and practicality, is becoming an indispensable "energy-saving eye" for future buildings.