How do broken bridge aluminum alloy casement windows improve thermal insulation, sound insulation, and structural strength?

Release Time : 2026-02-18

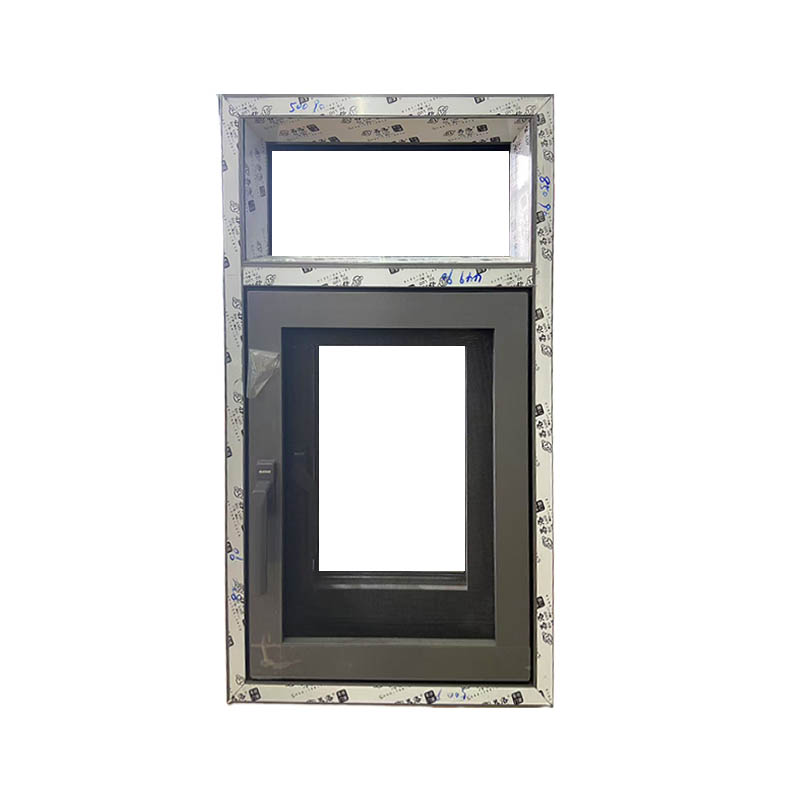

Broken bridge aluminum alloy casement windows, with their superior overall performance, have become the preferred window and door system for high-end residences, public buildings, and passive houses. They not only retain the advantages of lightweight, high strength, durability, and aesthetics of aluminum alloy materials, but also achieve significant breakthroughs in the three core performance aspects of thermal insulation, sound insulation, and structural strength through "broken bridge" thermal insulation technology and precise structural design. This systematic solution, integrating function and aesthetics, is redefining the standards for high-performance windows and doors.

1. Broken Bridge Thermal Insulation: Blocking Heat Transfer for Efficient Thermal Insulation

Traditional aluminum alloy profiles have a high thermal conductivity, easily forming "thermal bridges," leading to heat loss in winter and external heat intrusion in summer. The core of broken bridge aluminum alloy windows lies in embedding a low-thermal-conductivity thermal insulation strip between the inner and outer aluminum profiles, effectively cutting off the metal pathway. This "broken bridge" structure significantly reduces the overall window heat transfer coefficient, far superior to ordinary aluminum alloy windows.

2. Multi-cavity and Sealing System: Constructing Multiple Sound Barriers

Broken bridge aluminum alloy casement windows typically feature a multi-cavity structure in their profile cross-section, forming multiple closed or semi-closed air cavities that effectively block sound wave propagation paths. Furthermore, their casement structure is inherently superior to sliding windows—employing a multi-seal design that forms a continuous and tight sealing ring when the window sash is closed. When exposed to wind, rain, or noise, the outer seal blocks rainwater and high-frequency noise, the middle isobaric cavity balances air pressure and weakens mid-to-low frequency sound waves, and the inner seal prevents residual sound from seeping in.

3. Enhanced Structural Design: Dual Protection of Rigidity and Safety

Despite the addition of thermal break strips, broken bridge aluminum alloy windows do not sacrifice structural strength. On the contrary, through optimized cavity layout, thickened walls, and built-in reinforcing ribs, their wind pressure resistance is significantly improved. The wall thickness of the main load-bearing parts often reaches 1.8–2.0 mm, far exceeding national standards; some high-end products also embed stainless steel or aluminum reinforcing linings within the thermal break cavity to further enhance deformation resistance. The hinge and locking point linkage system of the casement window enhances overall rigidity—multi-point locking ensures the window sash evenly presses against the frame, improving not only airtightness and watertightness but also significantly increasing wind pressure resistance, making it suitable for high-rise buildings or typhoon-prone areas. Furthermore, its excellent torsional stiffness ensures no deformation or air leakage during long-term use, guaranteeing hardware lifespan and smooth opening.

4. System Integration: The Ultimate Embodiment of Performance Synergy

The broken bridge aluminum alloy casement window is not merely a collection of individual components, but a precise integration of five major systems: profiles, glass, sealing, hardware, and drainage. For example, the concealed pressure-equalizing drainage design achieves efficient drainage without compromising aesthetics; high-strength handles and multi-point locking mechanisms work together to ensure consistent sealing; glass spacers and flexible supports prevent stress concentration. This systematic approach ensures that insulation, soundproofing, and structural strength mutually reinforce each other, rather than compromising one another.

In summary, the broken bridge aluminum alloy casement window achieves a high degree of balance between energy saving, quiet operation, and safety through a four-pronged technological approach: thermal break insulation, multi-cavity sealing, reinforced structure, and system integration. It is not only a transparent interface for the building envelope but also an intelligent barrier protecting comfortable living—using advanced technology to build a beautiful life.

1. Broken Bridge Thermal Insulation: Blocking Heat Transfer for Efficient Thermal Insulation

Traditional aluminum alloy profiles have a high thermal conductivity, easily forming "thermal bridges," leading to heat loss in winter and external heat intrusion in summer. The core of broken bridge aluminum alloy windows lies in embedding a low-thermal-conductivity thermal insulation strip between the inner and outer aluminum profiles, effectively cutting off the metal pathway. This "broken bridge" structure significantly reduces the overall window heat transfer coefficient, far superior to ordinary aluminum alloy windows.

2. Multi-cavity and Sealing System: Constructing Multiple Sound Barriers

Broken bridge aluminum alloy casement windows typically feature a multi-cavity structure in their profile cross-section, forming multiple closed or semi-closed air cavities that effectively block sound wave propagation paths. Furthermore, their casement structure is inherently superior to sliding windows—employing a multi-seal design that forms a continuous and tight sealing ring when the window sash is closed. When exposed to wind, rain, or noise, the outer seal blocks rainwater and high-frequency noise, the middle isobaric cavity balances air pressure and weakens mid-to-low frequency sound waves, and the inner seal prevents residual sound from seeping in.

3. Enhanced Structural Design: Dual Protection of Rigidity and Safety

Despite the addition of thermal break strips, broken bridge aluminum alloy windows do not sacrifice structural strength. On the contrary, through optimized cavity layout, thickened walls, and built-in reinforcing ribs, their wind pressure resistance is significantly improved. The wall thickness of the main load-bearing parts often reaches 1.8–2.0 mm, far exceeding national standards; some high-end products also embed stainless steel or aluminum reinforcing linings within the thermal break cavity to further enhance deformation resistance. The hinge and locking point linkage system of the casement window enhances overall rigidity—multi-point locking ensures the window sash evenly presses against the frame, improving not only airtightness and watertightness but also significantly increasing wind pressure resistance, making it suitable for high-rise buildings or typhoon-prone areas. Furthermore, its excellent torsional stiffness ensures no deformation or air leakage during long-term use, guaranteeing hardware lifespan and smooth opening.

4. System Integration: The Ultimate Embodiment of Performance Synergy

The broken bridge aluminum alloy casement window is not merely a collection of individual components, but a precise integration of five major systems: profiles, glass, sealing, hardware, and drainage. For example, the concealed pressure-equalizing drainage design achieves efficient drainage without compromising aesthetics; high-strength handles and multi-point locking mechanisms work together to ensure consistent sealing; glass spacers and flexible supports prevent stress concentration. This systematic approach ensures that insulation, soundproofing, and structural strength mutually reinforce each other, rather than compromising one another.

In summary, the broken bridge aluminum alloy casement window achieves a high degree of balance between energy saving, quiet operation, and safety through a four-pronged technological approach: thermal break insulation, multi-cavity sealing, reinforced structure, and system integration. It is not only a transparent interface for the building envelope but also an intelligent barrier protecting comfortable living—using advanced technology to build a beautiful life.